Thermowells

Liqua-Tech meters utilize an innovative single-piece thermowell, eliminates the possibility of leakage. Competitive meters use two-piece units.

ATC Components

While other meter manufacturers have gone to the plastic construction of ATC ratchet arms to reduce production costs, Liqua-Tech has continued to produce ours from more durable

metal components.

Quick-Vent

Liqua-Tech was the first OEM manufacturer to offer the Full-Circle Quick-Vent bleed valve as a factory-

installed option.

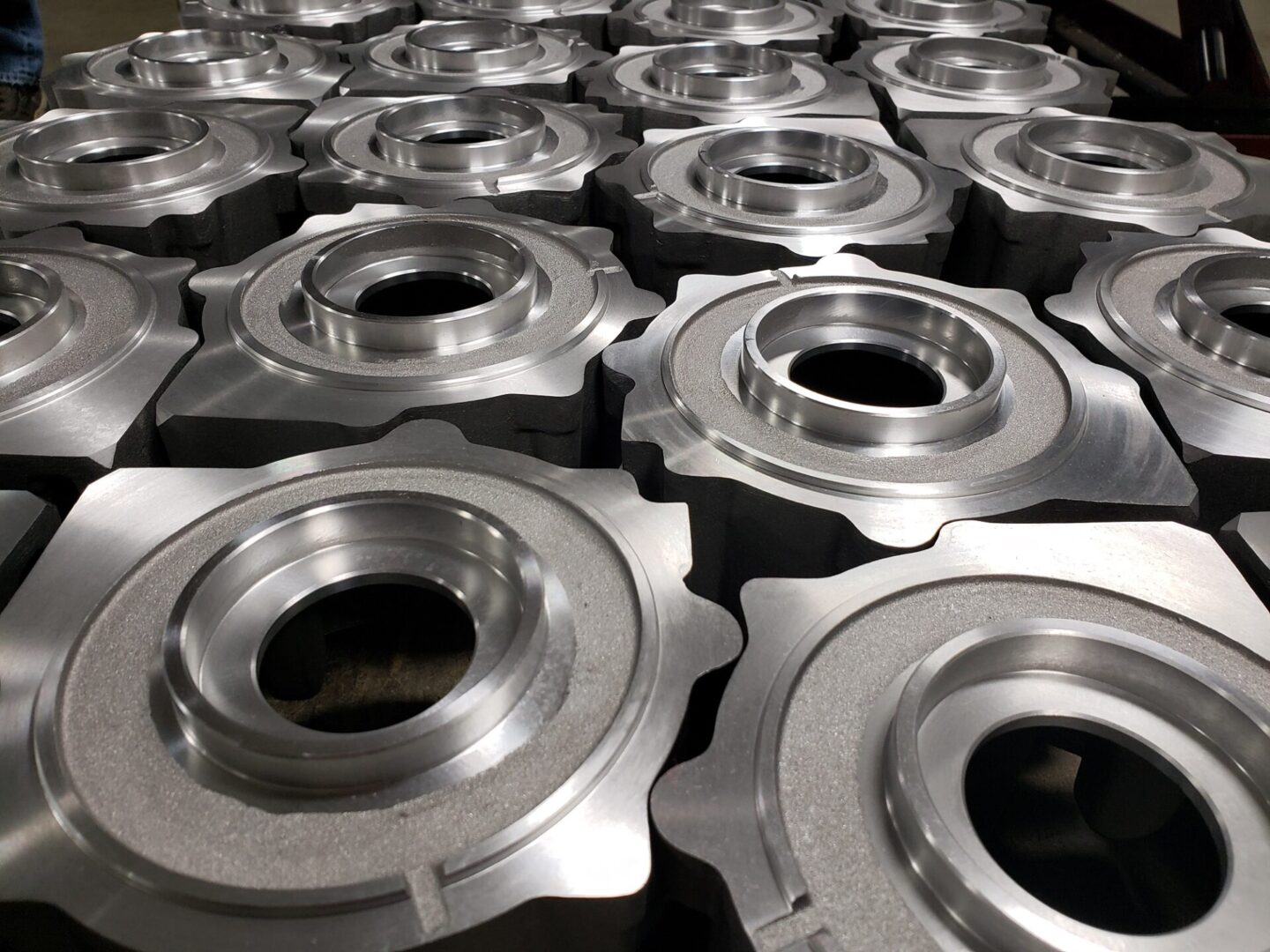

Gear Trains

Liqua-Tech’s higher quality gear trains utilize extensive use of bushings for increased longevity and

improved accuracy: